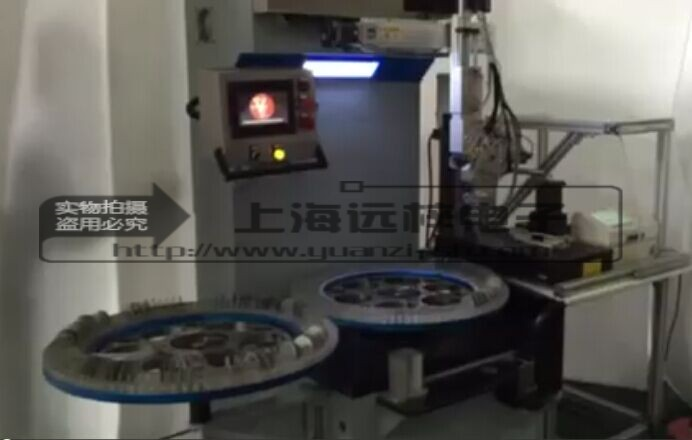

粗糙度仪VS硬度仪全自动送料系统S1400-A

English name:Surface roughness meter Automatic sampling tester

Model:S1400-A

Product brand:![]() 远梓

远梓

适用方向:项目粗糙度仪\硬度计等仪器自动送料,以减少操作员的工作强度,给使用方提出的具体技术要求及实施方案

Application direction: The project roughness meter \ hardness meter and other instruments automatic feeding, in order to reduce the work intensity of the operator, to the user of the specific technical requirements and implementation plan

仪器特点

设备的主要组成

粗糙度仪自动送料系统主要包括:

(1) 上料系统

上料系统包括走道、料斗、水平送料气缸、上下动作气缸、气爪及2个电机驱动机构。

(2) 下料及翻转系统

下料及翻转系统包括走道、翻转机构、水平送料气缸、上下动作气缸、气爪及落料机构。

(3) 控制系统

控制系统包括整个执行机构的控制、与测量仪本身的连接及与电脑连接口。

3.2 技术要求

(1) 本自动送料系统设计每次连续送料20片(可更改);

(2) 本自动送料系统的试验空间为全自动;

(3) 本自动送料系统可适应其它类似测量仪;

(4) 本自动送料系统可与测量仪及微机通讯;

(5) 本自动送料系统具有软硬件保护,行程保护,过载保护等多重保护功能;

(6) 本自动送料系统底座有足够的刚性;

(7) 考虑到可能误操作,装有可靠的安全防护罩、每步都有检测保护功能,同时,在设计时,对整套系统中易发生安全隐患的环节、部位,都考虑防护措施;

(8) 本自动送料系统设有停电保护装置;

(9) 本自动送料系统要有对故障进行声光报警功能。

The main components of the equipment

The roughness meter automatic feeding system mainly includes:

(1) Feeding system

The feeding system includes walkway, hopper, horizontal feeding cylinder, up and down action cylinder, air claw and 2 motor drive mechanisms.

(2) Feeding and turning system

The feeding and turning system includes walkway, turning mechanism, horizontal feeding cylinder, up and down acting cylinder, air claw and blanking mechanism

(3) Control system

The control system includes the control of the whole actuator, the connection with the measuring instrument itself and the connection with the computer.

Technical requirement

(1) The automatic feeding system is designed to continuously feed 20 pieces each time (can be changed);

(2) The test space of the automatic feeding system is fully automatic;

(3) This automatic feeding system can be adapted to other similar measuring instruments;

(4) The automatic feeding system can communicate with the measuring instrument and the microcomputer;

(5) The automatic feeding system has multiple protection functions such as software and hardware protection, stroke protection, overload protection, etc.

(6) The base of the automatic feeding system has sufficient rigidity;

(7) Considering the possibility of misoperation, equipped with a reliable safety shield, each step has a detection and protection function, at the same time, in the design, the whole system is prone to security risks in the links, parts, are considered protective measures;

(8) The automatic feeding system is equipped with power failure protection device;

(9) The automatic feeding system should have an audible and visual alarm function for the fault.

仪器参数

环境:

工作温度:-10~40℃

相对湿度:45%~80%

电源电压:220V±22V

电网频率:50HZ±1HZ

设备功率:1500W

采用7英寸PLC(台达)液晶多彩屏中文菜单显示;

(1)本自动送料系统设计每次连续送料至少100片,试验空间为全自动;

(2)送料系统可与测量仪及微机通讯;

(3)送料系统具有软硬件保护,行程保护,过载保护等多重保护功能;

(4)考虑到可能误操作,装有可靠的安全防护罩、每步都有检测保护功能,同时在设计时对整套系统中易发生安全隐患的环节、部位,都考虑防护措施;

(5)本自动送料系统设有停电保护装置,自动送料系统要有对故障进行声光报警功能;

(6)送料部分运行方式:打开电源,电机转动,带动同步带,同步带到达一定的位置;

(7)通知机器人手臂进行抓取样品,抓取样品通过机器人手臂控制器进行设定,可任意设定位置,距离位置精度达到0.02mm;

(8)通过I/O对冲床前端模块,送料机构,机械人手臂粗糙度仪进行互联,样件送料到位通知机械 手抓取,抓取完毕;

(9)送往粗糙度仪并通知粗糙度仪进行粗糙度的测试,测试完毕后通知机械人手臂送三点位置与反 面的测试;

(10)机械手臂技术参数:测试一面与二面可直接机械手臂控制器设定,测试完毕后通知机器人手臂抓取式样送往料框,再抓取第二个样品进行下次测试,测试速度为4分钟/块),机械手臂品牌:ABB品牌,六轴联动,位置调节更准确;

Environment: Working temperature: -10 ~ 40℃ Relative humidity: 45% ~ 80% Power supply voltage: 220V±22V Network frequency: 50HZ±1HZ Equipment power: 1500W Using 7-inch PLC(Delta) LCD multi-color screen Chinese menu display; (1) The automatic feeding system is designed to continuously feed at least 100 pieces each time, and the test space is fully automatic; (2) The feeding system can communicate with the measuring instrument and the microcomputer; (3) The feeding system has multiple protection functions such as software and hardware protection, stroke protection, overload protection, etc. (4) Considering the possibility of misoperation, equipped with a reliable safety shield, each step has a detection and protection function, and at the same time, consider protective measures for the links and parts prone to safety hazards in the whole system during the design; (5) The automatic feeding system is equipped with a power failure protection device, and the automatic feeding system should have an audible and visual alarm function for the fault; (6) The operation mode of the feeding part: turn on the power, the motor rotates, drives the synchronization belt, and the synchronization belt reaches a certain position; (7) Notify the robot arm to grab the sample, and the grabbing sample can be set by the robot arm controller, and the position can be set arbitrarily, and the distance position accuracy can reach 0.02mm; (8) Interconnect the front end module of the punch press, the feeding mechanism and the roughness meter of the robot arm through I/O, and notify the mechanical hand to grasp the sample when it is in place. (9) Send to the roughness meter and inform the roughness meter to test the roughness, and notify the robot arm to send the three-point position and the opposite side of the test after the test is completed; (10) Technical parameters of the mechanical arm: the test side and the second side can be directly set by the controller of the mechanical arm. After the test is completed, the robot arm can be notified to send the grabbing pattern to the material frame, and then grab the second sample for the next test, the test speed is 4 minutes/piece). The brand of the mechanical arm: ABB brand, six-axis linkage, and the position adjustment is more accurate;

售后服务

维修和保养

1. 保修期限:保修期为12个月。

2. 设备到达现场后,卖方根据双方约定的时间,派遣工程师到现场进行安装调试,保修期将于验收合格起计算。

3. 保修服务:保修期内的设备,均可获得免费维修服务及故障件更换。

4. 技术培训:

1)在设备安装现场,乙方的工程师将提供现场培训,培训内容包括: 设备的使用,维修,保养等,确保客户能够正确使用该设备,进行常规维修保养(2天),程控器的编程培训。

2)终身提供应用支持,解决各种技术问题。

5. 客户在设备使用过程中遇到问题,乙方工程师将在第一时间内通过电话帮助客户解决问题。如果通过电话仍然无法排除故障, 乙方将在半个工作日内做出响应,并确保维修工程师在2个工作日内到达现场。

Repair and maintenance

1. Warranty period: The warranty period is 12 months.

2. After the equipment arrives at the site, the seller shall send engineers to the site for installation and commissioning according to the time agreed by both parties. The warranty period shall be calculated from the acceptance.

3. Warranty service: The equipment within the warranty period can be repaired for free and replaced with faulty parts.

4. Technical Training:

1) At the equipment installation site, Party B's engineers will provide on-site training, including: equipment use, repair, maintenance, etc., to ensure that customers can correctly use the equipment, routine maintenance (2 days), programming training of the program controller.

2) Provide lifelong application support and solve various technical problems.

5. If the customer encounters any problem during the use of the equipment, the engineer of Party B will help the customer solve the problem through telephone in the first time. If the fault still cannot be removed by phone, Party B will respond within half a working day and ensure that the maintenance engineer arrives at the scene within 2 working days.