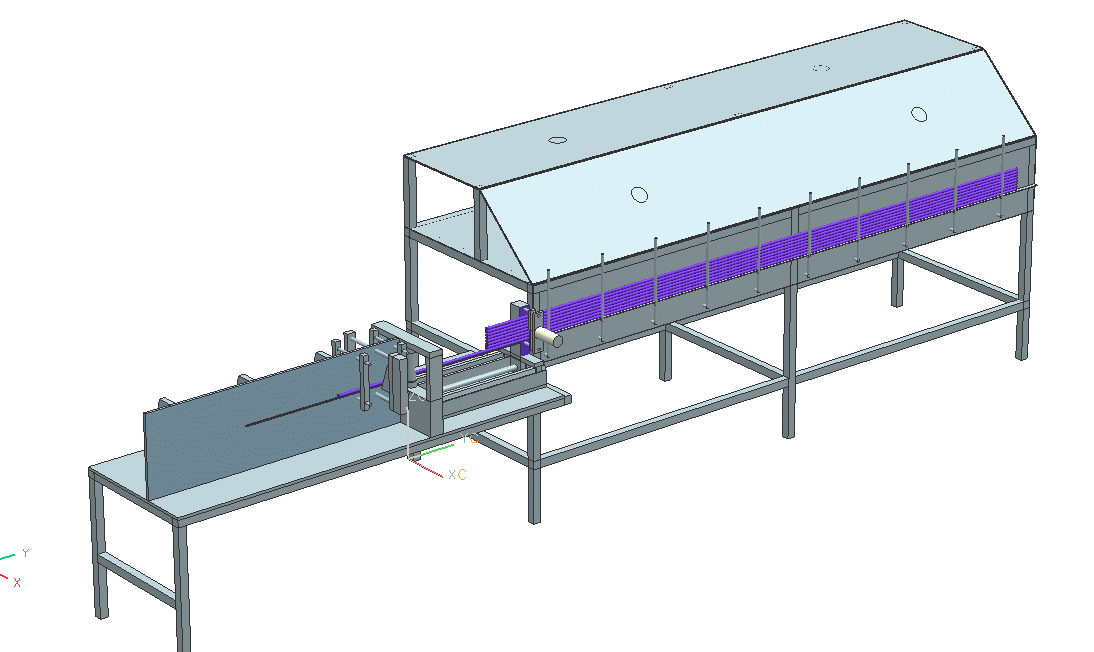

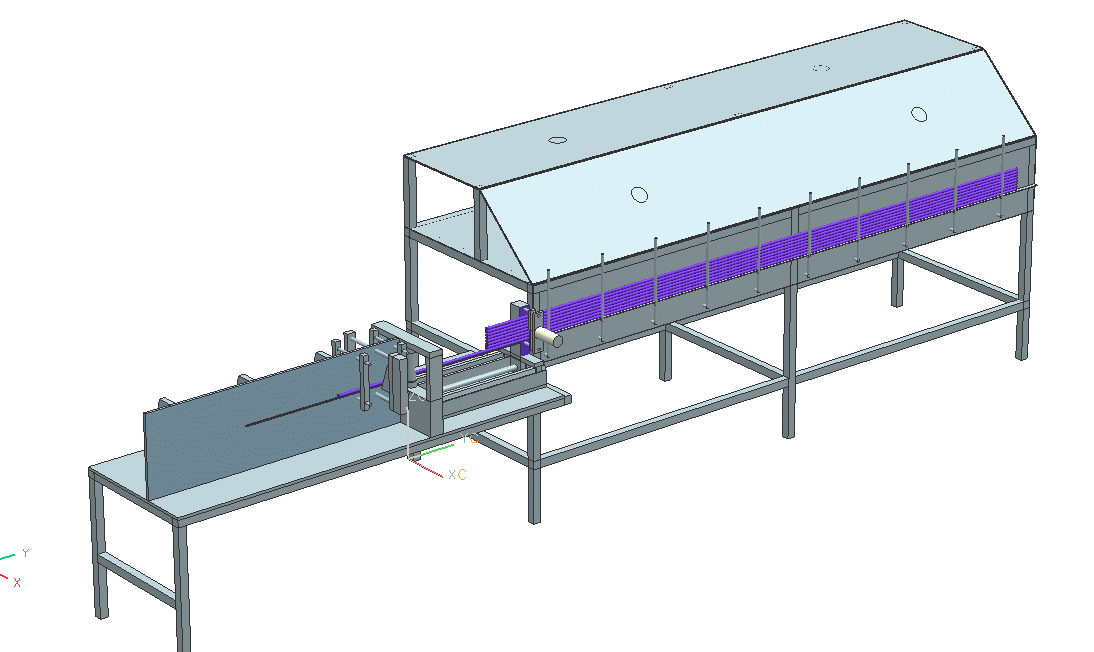

软管全自动落料划线机YZ-10A型

English name:Hose automatic blanking marking machine

Model:YZ-10A型

Product brand:![]() 远梓

远梓

适用方向:本项目主要用于软管全自动落料划线机,划线机应符合相应行业标准对软管落料划线设备的要求,产品外形美观,能可靠地连续对软管全自动落料划线。

Application direction: This project is mainly used for hose automatic blanking and scribing machine. The scribing machine should meet the requirements of the corresponding industry standards for hose blanking and scribing equipment. The product is beautiful in appearance and can reliably and continuously streak the hose automatic blanking and scribing.

仪器特点

本项目主要用于软管全自动落料划线机,划线机应符合相应行业标准对软管落料划线设备的要求,产品外形美观,能可靠地连续对软管全自动落料划线。

1.设计技术指标

1.1 基本原则

对软管全自动落料划线。设备具有对胶管全自动送料、落料、两端划线、废料分拣的功能。通过调节落料装夹夹具可对甲方招标书上附表每种产品所列各型号胶管全自动落料划线和印字等功能要求。

1) 调试试样由甲方负责。

2) 设备各工装、模具、辅助装置可调节、可互换检修方便。

3) 设备为双头,各工位可单独控制。

4) 落料两端面垂直胶管轴心线。

5) 划线清晰,不易擦除,划线颜色可换(现用白色)。

6) 传料速度可调整。

7) 专机电气系统采用PLC程序控制,采用触摸屏显示和操作,设备可通过人机界面显示相应时间、速度、产量设定、产量记录、动作工位、故障指示等。

8) 如果乙方因非甲方原因改变了分交表中设备、零部件和材料的型号或数量,改变部分由乙方负责供货。

9) 甲方工作环境:

10) 电源:3相五线380V±10%,50±5HZ

11) 环境温湿度:温度:5-45℃

12) 工作方式:3班,每日工作时间24小时

This project is mainly used for hose automatic blanking and scribing machine. The scribing machine should meet the requirements of the corresponding industry standards for hose blanking and scribing equipment. The product is beautiful in appearance and can reliably and continuously streak the hose automatic blanking and scribing.

1. Design technical indicators

1.1 Basic Principles

Automatic blanking marking for hose. The equipment has the functions of automatic feeding, blanking, marking at both ends and sorting waste. By adjusting the blanking clamping fixture, the functional requirements of automatic blanking marking and printing for each type of rubber hose listed in each product attached to the bidding book of Party A can be met.

1) Party A shall be responsible for commissioning the sample.

2) The equipment tooling, mold, auxiliary device can be adjusted, interchangeable maintenance is convenient.

3) The equipment is double-headed, and each station can be controlled separately.

4) blanking two vertical rubber hose axis line.

5) The line is clear, not easy to erase, and the color of the line can be changed (now white).

6) The transfer speed can be adjusted.

7) The electrical system of the special plane adopts PLC program control, and adopts touch screen display and operation. The equipment can display the corresponding time, speed, output setting, output record, action station, fault indication, etc., through the man-machine interface.

8) If Party B changes the type or quantity of equipment, parts and materials in the delivery table for reasons other than Party A, Party B shall be responsible for supplying the changed part.

9) Working environment of Party A:

10) Power supply: 3-phase 5-wire 380V±10%, 50±5HZ

11) Ambient temperature and humidity: Temperature: 5-45℃

12) Working mode: 3 shifts, 24 hours a day

仪器参数

1.落料划线机型号:YZ-10A型

2. 落料划线机名称: 程控全自动双头单控软管落料划线机

3. 落料软管范围: ¢9~¢12(mm)

4. 主机驱动方式: 电动窝轮式

5. 主控制: PLC

6. 显示系统: 触摸屏人机界面

7. 送料系统: 伺服(或变频)电机带动摩擦轮送料

8. 划线系统: 漆(墨)喷嘴装置

9. 工作速度: 14次∽16次/min,每班产量为10000∽12000根左右。

10. 显示内容: 工序、参数、产量及故障提示

11. 报警: 声光报警系统

12. 电源功率: 0.75kW(380v/220v三相五线制,50Hz)

13. 安全保护装置: 电机超温保护、切割力过载保护及人身安全保护

14. 主机外形尺寸: 1760x900x800

15. 重量: 2000kg

1. Blanking line model No. : YZ-10A

2. Blanking marking machine name: program controlled automatic double head single control hose blanking marking machine

3. Blanking hose range: ¢9 ~ ¢12(mm)

4. Host drive mode: electric motor wheel type

5. Main control: PLC

6. Display system: touch screen man-machine interface

7. Feeding system: servo (or frequency conversion) motor drives friction wheel feeding

8. Marking system: paint (ink) nozzle device

9. Working speed: 14 ∽16 times /min, the output per class is about 10000∽12000.

10. Display content: process, parameters, output and fault tips

11. Alarm: sound and light alarm system

12. Power supply: 0.75kW (380v/220v three-phase five-wire system, 50Hz)

13. Safety protection device: motor overtemperature protection, cutting force overload protection and personal safety protection

14. Dimensions of the host: 1760x900x800

15. Weight: 2000kg

售后服务

维修和保养

1. 保修期限:保修期为12个月。

2. 设备到达现场后,卖方根据双方约定的时间,派遣工程师到现场进行安装调试,保修期将于验收合格起计算。

3. 保修服务:保修期内的设备,均可获得免费维修服务及故障件更换。

4. 技术培训:

1)在设备安装现场,乙方的工程师将提供现场培训,培训内容包括: 设备的使用,维修,保养等,确保客户能够正确使用该设备,进行常规维修保养(2天),程控器的编程培训。

2)终身提供应用支持,解决各种技术问题。

5. 客户在设备使用过程中遇到问题,乙方工程师将在第一时间内通过电话帮助客户解决问题。如果通过电话仍然无法排除故障, 乙方将在半个工作日内做出响应,并确保维修工程师在2个工作日内到达现场。

Repair and maintenance

1. Warranty period: The warranty period is 12 months.

2. After the equipment arrives at the site, the seller shall send engineers to the site for installation and commissioning according to the time agreed by both parties. The warranty period shall be calculated from the acceptance.

3. Warranty service: The equipment within the warranty period can be repaired for free and replaced with faulty parts.

4. Technical Training:

1) At the equipment installation site, Party B's engineers will provide on-site training, including: equipment use, repair, maintenance, etc., to ensure that customers can correctly use the equipment, routine maintenance (2 days), programming training of the program controller.

2) Provide lifelong application support and solve various technical problems.

5. If the customer encounters any problem during the use of the equipment, the engineer of Party B will help the customer solve the problem through telephone in the first time. If the fault still cannot be removed by phone, Party B will respond within half a working day and ensure that the maintenance engineer arrives at the scene within 2 working days.