仪器特点

产品特点:

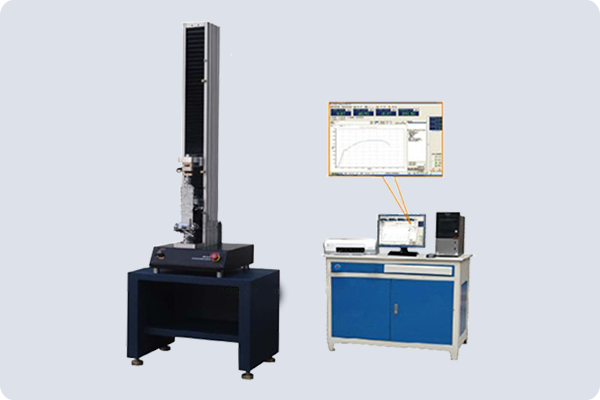

主要针对橡胶导管,橡胶手套等产品进行伸长率的测试.具有应力、应变、位移三种闭环控制方式,可求出最大力、抗拉强度、弯曲强度、压缩强度、弹性模量、断裂延伸率、屈服强度等参数。根据YYT1710-2020、GB及ISO、JIS、ASTM、DIN等国际标准进行试验和提供检测数据。并能对试验数据曲线进行叠加分析处理、存储、打印、绘制曲线,打印完整报告单,进行工艺调整与生产控制。机型结构均充分考虑了现代工业设计,人体工程学之相关原则,外壳采用合金框架构以增强刚度系数及表面双层金属烤漆,延长主机使用寿命及美化外观。上下空间兼可应用.

Product features:

Mainly for rubber catheter, rubber gloves and other products elongation test. With three closed-loop control modes of stress, strain and displacement, the maximum force, tensile strength, bending strength, compressive strength, elastic modulus, elongation at break, yield strength and other parameters can be calculated.

Test and provide test data according to YYT1710-2020, GB, ISO, JIS, ASTM, DIN and other international standards. And the test data curve can be superposition analysis, storage, print, draw curves, print a complete report, process adjustment and production control.

The structure of the machine fully considers the principles of modern industrial design and ergonomics. The shell adopts alloy frame structure to enhance the stiffness coefficient and double metal paint on the surface to extend the service life of the main engine and beautify the appearance.

Both upper and lower space can be used.

仪器参数

电脑显示: 联想电脑+液晶显示器+佳能打印机

执行标准:YYT1710-2020、GB及ISO、JIS、ASTM、DIN等国际标准

测试项目:拉力项目

动力系统:专业日本松下伺服机电组+专业Panasonic交流伺服控制器+德国行星变速器+专业台湾HIWIN高精密导向系统

控制系统:微机液晶屏显示+材料试验机专业数字伺服控制系统

单位选择:Gf、Kgf、N、KN、LB、Mpa(根据需要任意选择)

最大载重 :500N(全程可分段控制)

感应方式:标配德国HBM高精密负荷传感器500N壹套

荷重精度:±0.01%

力分辨率:±1/500000F.S(全程分辨力不变)

测量范围:0-1KN(具有载荷量程自动切换功能)

测量精度:示值的±0.5%以内

位移分辨率: 0.0001mm(采用高精度位移传感器跟踪测试)

位移测量精度:示值的±0.5%以内

试验控速范围:0.01-500mm/min分段控制,无级调速(可调)

试验控速精度:速度<0.1mm/min时,为设定值的±1%以内;

速度≥0.1mm/min时,为设定值的±0.2%以内

恒力/位移/变形测量范围:0.5%~100%FS

恒力/位移/变形测量精度:设定值<10%FS时,为设定值的±1%以内;

设定值:≥10%FS时,为设定值的±0.1%以内;

试验宽度:200mm

最大行程:650mm

安全装置:系统具有激光限位保护装置,自动诊断功能,定时对测量系统、驱动系统进行过载、过压、超负等检查,出现异常情况立即进行保护

精度等级:0.5级

试验工装:标配试验专用夹具壹套(用于试件的拉力测试及定荷重保持力测试)

电 源: AC 220V 50HZ 0.37KW

质保 :1年

发货清单:主机一台、配电脑一台、合格证、配套夹具、操作说明书

升级说明 仪器软件终身免费依国家标准规定升级服务、终身维护

Computer display: Lenovo PC + LCD + Canon printer

Implementation standards: YYT1710-2020, GB and ISO, JIS, ASTM, DIN and other international standards

Test item: Pull item

Power system: Professional Japanese Panasonic servo group + professional Panasonic AC servo controller + German planetary transmission + professional Taiwan HIWIN high precision steering system

Control system: microcomputer LCD screen display + material testing machine professional digital servo control system

Unit selection: Gf, Kgf, N, KN, LB, Mpa (optional as required)

Maximum load: 500N (the whole process can be controlled in stages)

Induction mode: Standard German HBM high precision load sensor 500N one set

Load accuracy: ±0.01%

Force resolution: ±1/500000F.S (full resolution unchanged)

Measuring range: 0-1KN (with load range automatic switching function)

Measurement accuracy: within ±0.5% of the indicated value

Displacement resolution: 0.0001mm (using high-precision displacement sensor tracking test)

Displacement measurement accuracy: within ±0.5% of the indicated value

Test speed control range: 0.01-500mm/min segmented control, stepless speed regulation (adjustable)

Test speed control accuracy: when the speed is less than 0.1mm/min, it is within ±1% of the set value;

When the speed is ≥0.1mm/min, it is within ±0.2% of the set value

Constant force/displacement/deformation measurement range: 0.5% ~ 100% FS

Constant force/displacement/deformation measurement accuracy: set value < 10%FS, within ±1% of the set value;

Set value: ≥ 10% FS, within ±0.1% of the set value;

Test width: 200mm

Maximum travel: 650mm

Safety device: The system has a laser limit protection device, automatic diagnosis function, regular overload, overvoltage, super negative inspection of the measuring system and drive system, and immediately protect the abnormal situation

Accuracy level: 0.5

Test equipment: standard test fixture (used for tensile test and constant load retention test)

Power supply: AC 220V 50HZ 0.37KW

Warranty: 1 year

Delivery list: one host, one computer,

售后服务

整机质保壹年

上门培训维修

七天质量问题全款退换货服务

仪器软件终身免费依国家标准规定升级服务、终身维护

The whole machine quality guarantee one year

door-to-door training maintenance

seven days quality problem full-money return service

instrument software life-long free according to the national standard upgrade service, life-long maintenance