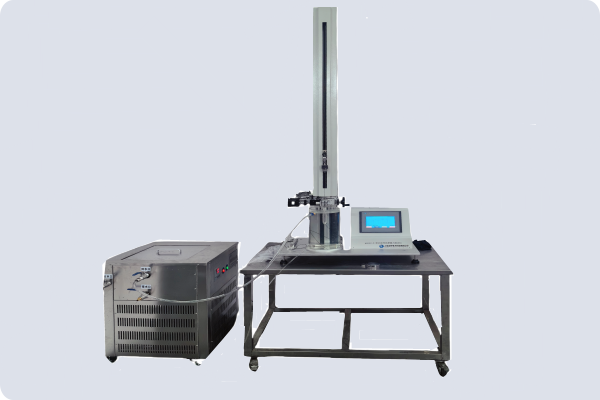

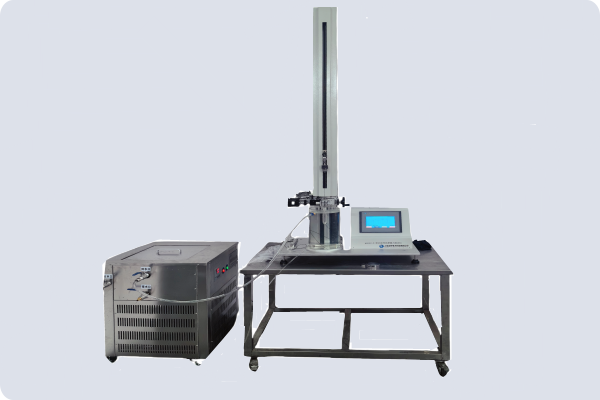

亲水层导丝摩擦力测试仪 MCL021-D

English name:Hydrophilic layer wire friction tester

Model:MCL021-D

Product brand:![]() 远梓

远梓

适用方向:一次性使用亲水涂层导丝附录A的要求设计制造的。摩擦力(包含拉伸机构、夹紧机构和水浴机构)。

Application direction: Designed and manufactured for one-time use of hydrophilic coating guide wire as required by Appendix A. Friction force (including tension mechanism, clamping mechanism and water bath mechanism).

仪器特点

采用7英寸K600+内核/点阵式65色 800*480分辨率触摸屏显示,PLC控制系统动态显示加载力值;操作界面可选:中文/英文/中英文切换;采用数字闭环控制,AD采集速度为500KHz,内码100万;高精度时钟芯片,断电存储;PLC控制动态显示加载力值;过载报警停机保护;

触控操作:公称规格、测试、上行、下行、时间、标定。可与上位微机通讯,方便实验数据处理;机载打印测试数据,实时显示拉力

Using 7-inch K600+ core/dot-matrix 65 color 800*480 resolution touch screen display, PLC control system dynamically displays the loading force value; Operation interface Optional: Chinese/English/English switch; Adopts digital closed-loop control, AD acquisition speed is 500KHz, internal code 1 million; High precision clock chip, power off storage; PLC control dynamic display loading force value; Overload alarm stop protection;

Touch operation: nominal specification, test, up, down, time, calibration. It can communicate with PC to facilitate experimental data processing. On-board printed test data, real-time display of tension

仪器参数

执行标准:T-CAMDI 021—2019 一次性使用亲水涂层导丝附录A的要求设计制造的。摩擦力(包含拉伸机构、夹紧机构和水浴机构)

拉断力测试范围:0~5N, 误差不大于±1%,分辨率0.01N。

加持力:5N±0.5N

时间设定:1-99S, 误差不大于±0.5S。

测试速度:100mm/min误差不大于±5%。;

设定距离:10mm~100mm

打印方式: 每次可打印8次、10次测试数据或13次测试数据及平均刺穿力和偏差值。

试验方法:

1. 取一根待测导丝,剪裁含有亲水不涂层区域作为没试管体,泥鳅导丝裁剪任意260±10mm长度,混合导丝裁剪前端黑色管体部分50±5mm长度;

2. 在摩擦力测试仪的水浴单元中加入足够量的纯化水;

3. 将测试管体固定在特制的试样夹具,保证被测样品与试样夹的中心在同一条直线上,将试样夹悬挂在拉伸机构的夹头上后,被测样品自然垂落,保持垂直方向,完成试样的放置;

4. 移动拉伸机构,将导丝浸入水浴机构的纯化水内,保持1min;

5. 以300g夹紧力和20mm/sec速度条件,并且泥鳅导丝测试长度100mm±10mm、混合导丝测试长度30mm±5mm,连续测试5次

6. 每组被测试样品测试5次,摩擦阻力数值不超过2N判定为合格

Implementation standard: T-CAMDI 021-2019 Single-use hydrophilic coating guide wire Appendix A design and manufacture. Friction force (including tension mechanism, clamping mechanism and water bath mechanism)

Tensile force test range: 0 ~ 5N, error is not more than ±1%, resolution 0.01N.

Holding force: 5N±0.5N

Time setting: 1-99S, error is not more than ±0.5S.

Test speed: 100mm/min error is not more than ±5%. ;

Setting distance: 10mm~100mm

Printing method: Each time can print 8, 10 test data or 13 test data and the average piercing force and deviation value.

Test method:

1. Take a guide wire to be tested and cut the area containing hydrophilic uncoated area as the blank tube body. Cut the guide wire to any length of 260±10mm, and cut the black tube body at the front end of the mixed guide wire to 50±5mm length;

2. Add sufficient amount of purified water to the water bath unit of the friction tester;

3. Fix the test tube body on the special sample fixture to ensure that the center of the tested sample and the sample clamp are in the same straight line. After the sample clamp is suspended on the clamp of the tensile mechanism, the tested sample will naturally fall and maintain the vertical direction to complete the placement of the sample;

4. Move the drawing mechanism, immerse the guide wire in the purified water of the water bath mechanism, and keep it for 1min;

5. Under the conditions of 300g clamping force and 20mm/sec speed, the test length of loach guide wire is 100mm±10mm, and the test length of mixed guide wire is 30mm±5mm, and the test length is continuous for 5 times

6. Each group of tested samples is tested 5 times, and the frictional resistance value does not exceed 2N

售后服务

整机质保壹年

上门培训维修

七天质量问题全款退换货服务

仪器软件终身免费依国家标准规定升级服务、终身维护

The whole machine quality guarantee one year

door-to-door training maintenance

seven days quality problem full-money return service

instrument software life-long free according to the national standard upgrade service, life-long maintenance